Group II base oil migration in hydraulic oil formulations

Oxidation has been the enemy of hydraulic oils since their inception, arising from various sources including thermoxidative-degradation, wear metal ingress, air entrainment and a plethora of possible contaminants arising from its use. The goal of the formulator is to delay, pacify, prevent or disrupt these processes, enabling prolonged lubrication under all operating regimes the fluid was originally designed for. Whilst various additives can address the fundamental principles of oxidation, the underling fact is that >90% of the formulation is solely a hydrocarbon source and therefore the selection of base fluid has become ever more critical to meet the demands of modern hydraulic systems, with ever increasing demands for prolonged drain times.

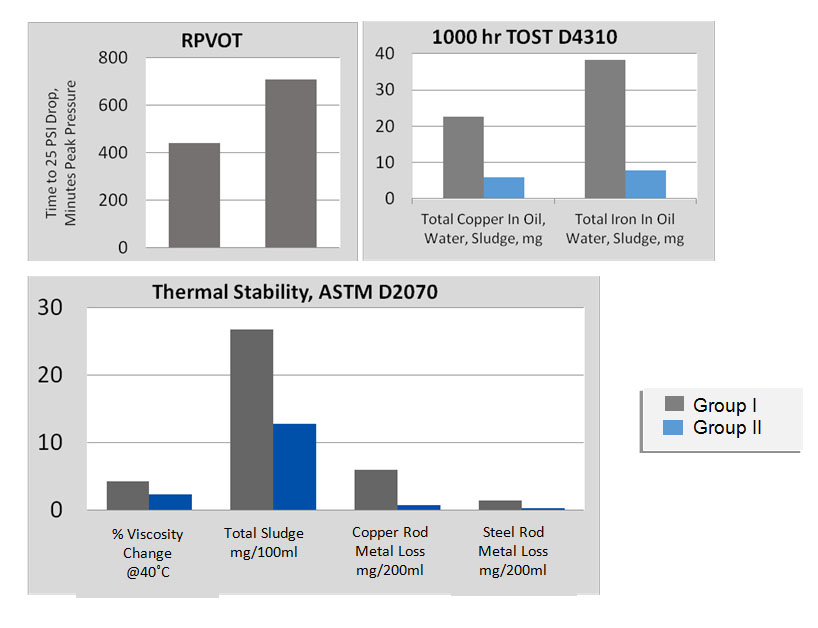

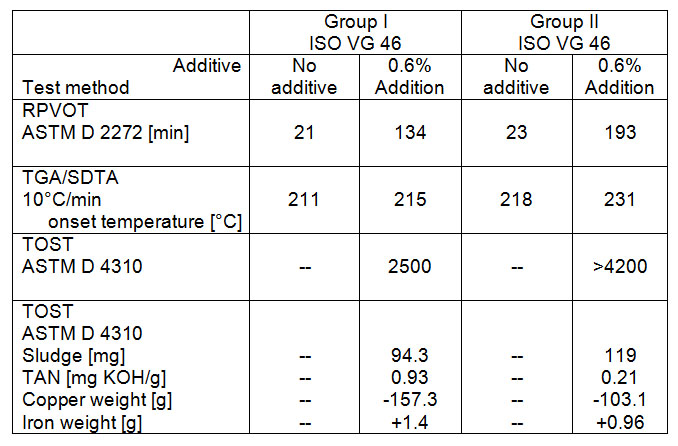

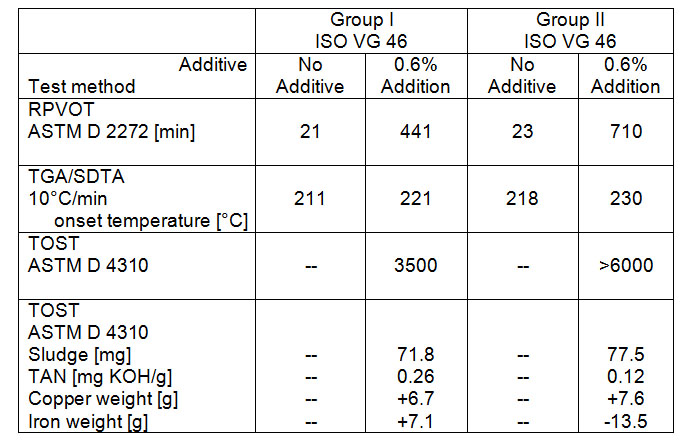

Changes to PCMO and HDEO engine oils over the last decade have made Group II base oils more accessible and therefore they have naturally found their way into industrial applications. But the mere 1:1 substitution over previously optimised formulations on Group I does not necessarily produce a better hydraulic fluid. The higher levels of Sulphur in Group I base oils are, by design themselves, oxidation inhibitors before considering the impact of higher saturation on solubility. The graphs below summarise the increased oxidative stability when switching to Group II base stocks and, whilst the selection of base stocks within Grouping can be further explored, it is not the intention of this report to compare base sources within groups but to highlight the general trend in oxidative performance.

Data based upon fully formulated fluids

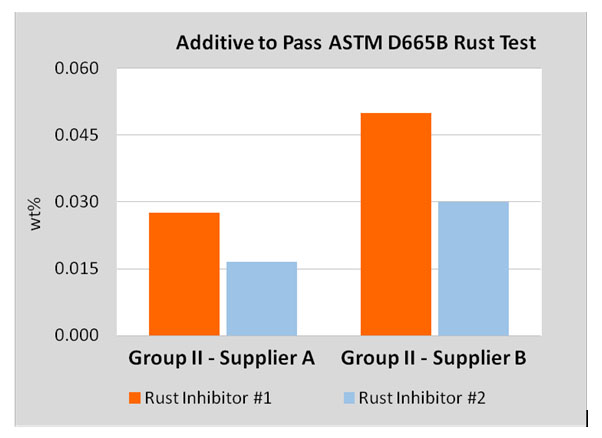

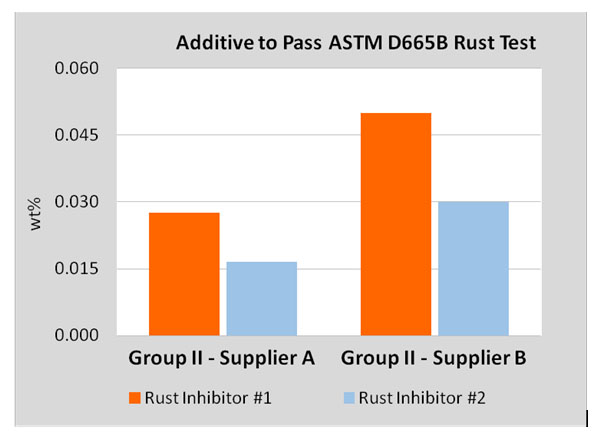

With >60% of industrial oils being hydraulic - and of those 98% can be formulated with Group II base stocks - development is progressing on the basis of better filterability, air release and oxidative stability over that of Group I; however, the benefits of Group II are not always realised over Group I, for example rust inhibition according to ASTM D665B. Here the selection of Group II stocks according to supplier does show differences and necessitates the need for testing protocols to ensure the supply of product fit for purpose.

As with all technologies, adoption into the market place will vary from simple introduction to formulations - based upon proprietary additives – to a full programme of development looking at individual additives response using a specific base stock/supplier. Whilst various discussions can be undertaken into the use of existing technologies, only by the adoption of targeted development can the true benefits of base stock selection be realised.

Hydraulic formulations come in a variety of guises from ash to ashless and therefore their response will no doubt differ in Group I and Group II stocks, the question however is of course by how much? If we look at a typical ash and ashless additive package commonly available in the market place we can see how again the performance changes simply by changing out the base stocks from Group I to Group II.

Ash containing hydraulic Additive package

Ashless hydraulic Additive package

From the results obtained, the ashless additive response was found to be far superior over that of a typical ash containing hydraulic oil, particularly with respect to oxidation as per RPVOT.

To conclude, it is possible using existing technology to provide enhanced products to the market by simply switching base oils, no doubt a route which will be taken where investment in time and resources is critical. The downside of such actions are obvious and, indeed, have been highlighted here particularly in the case of corrosion protection, sludge which may or may not be exacerbated by a lack of QA controls on the formulated fluids. There is nothing new with regards to optimised formulations and products in the market place but with the ease at which Group II can be substituted within existing formulations with the pretence of increased stability, it is the duty of all suppliers of product to the market place to ensure claims and approvals are being met.

News List News List

- Morris Lubricants launches new, innovative 5W-20 engine oil for Scania and MAN

- New Product Bulletin: ULTRALIFE HD (Yellow) Organic Acid Technology Antifreeze

- New Product Bulletin: Magnol HVI 46

- New Product Bulletin: Workshop PRO Aerosol Range

- Race wins set Wood up for British Pickup Racing Championship challenge

- IMPORTANT: Morris Lubricants Automotive Engine Oil Brand Updates - November 2016

- Morris Lubricants fuels family’s sidecar racing success

- Morris Lubricants adds weight to Strongest Disabled Man contest

- Morris Lubricants Racing revs up support for grassroots British motorsport

- Automechanika debut success for Morris Lubricants

Information

© 2013 - 2024 Morris Lubricants Online. Design by Lesniak Swann

Updated cookies policy - Morris Lubricants Online use cookies on this website. They help us to know a little bit about you and how you use our website, which improves the browsing experience and marketing - both for you and for others. They are stored locally on your computer or mobile device. To accept cookies continue browsing as normal. Or go to the Cookie Policy page for more information and preferences.

Morris engine oils and lubricants, egine oils, machine oils, diesel engine oils, gear oil, and classic car oil. Morris Lubricants specialist oil, lubrications, biodegradable lubricants, synthetic biodegradable marine two stroke lubricant and outboard engine oils. Agricultural oils, forestry lubricants, horticultural oil and water lubricants.